While flat roofs are a superb solution for schools, leisure centres and other commercial buildings; failing to factor in fire risks during hot works at the design stage can have catastrophic consequences. Daniel Tucker discusses the NFRC’s Safe2Torch campaign and associated manufacturer support.

Roof fires caused by gas torches, no matter how minor, pose a threat to the user, product, property and, in extreme circumstances, to life and will potentially impact the long-term future of torch-on as an accepted method of roof covering.

Under the Construction (Design and Management) Regulations 2015 (CDM 2015), specification writers have a statutory responsibility to manage any risks they may create through their designs. One element of this is the risk of fire during construction, and it is essential to make sure all fire risks are identified at the survey stage and factored in to the specification before it is written.

This means that anyone writing a flat roof specification, which involves hot works needs to assess the hazards associated with the works and design out, or greatly reduce, the risks of fire.

Hot works refers to a process that includes a source of ignition and has the potential to create a significant fire safety risk. Common hot works include cutting, grinding, welding, torch-on roofing, bitumen boiler work and drying substrates with a torch before application of roof system — all of which can form part of flat roof installation.

Where a combustible material is present, or the risk of fire occurs, or the risk is not known; an alternative, torch-free solution should be specified from the outset — although this can just be local to the risk area. This means that while torch-on membranes are safe, the specification needs to reflect areas where risk could exist.

To this end, the National Federation of Roofing Contractors (NFRC) launched Safe2Torch in November 2017. Safe2Torch, developed in partnership with contractor and manufacturer members of the NFRC, quite simply seeks to reduce the risk of roof fires when using gas torches. The campaign is designed to support specification writers in complying with CDM 2015 and ties in with the HSE-led Helping Great Britain Work Well strategy, which promotes a safer and healthier working environment.

Safe2Torch guidelines

In the 18 months since launch, great strides have been made across the sector to ensure awareness and implementation of the Safe2Torch guidelines and processes; with the NFRC and its supporters still working hard to see it become the default design approach in all flat roofing applications involving hot works.

As an example of these efforts, manufacturers must — in addition to being an NFRC supplier member — follow Safe2Torch guidance and checklist when writing specifications; and have the range of materials to satisfy the specification.

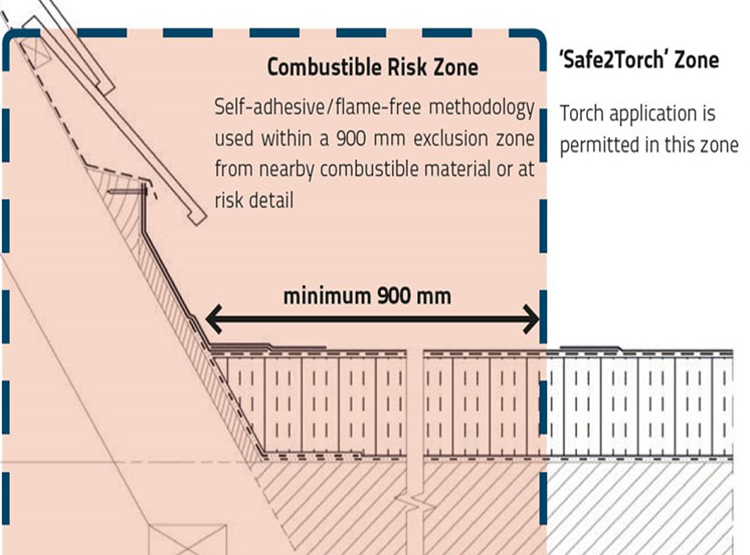

Under Safe2Torch, specification writers must always undertake a site inspection prior to works to ensure that any fire risks have been identified and whether alternative products other than torch-on are suitable. The specification, and any Safe2Torch roof plan — which highlights the areas where it is not Safe2Torch — must always be available in the tender package and on the roof. It is also recommended to mark areas that are not Safe2Torch on the actual roof prior to commencement of work.

Many of the design considerations and steps that would be taken to eliminate fire risk — such as recognising that timber decks can burn; that open perpends can track flame into cavities or that flame proximity to combustible materials, such as timber cladding, is hazardous — might seem like common sense. Yet these can still be overlooked in practice, and the criteria for safe practice could not be easier and more accessible thanks to the detailed guidance and comprehensive checklist published by the NFRC.

Best practice

Campaign registration is set to become mandatory for all CompetentRoofer and NFRC members involved with flat roofing; and this should prove a great incentive for designers and specifiers to write membership and/or scheme registration into their requirements

For their part, Safe2Torch contractors must follow scheme guidance and a checklist when writing specifications; follow Safe2Torch guidance when using a gas torch either for drying out and/or installation work; carry out work using flame-free solutions when appropriate and carry out robust fire checks after hot works have finished.

One requirement placed on the specifier by Safe2Torch is the identification of ‘exclusion zones’ which separate combustion risk and Safe2Torch zones, and then specifying a suitable means of detailing using cold or ‘cool work’ materials and installation techniques. These exclusion zones could be, for instance, where pitched roofs and flat roofs meet at eaves, or junctions with plain tile cladding; or around window cills and roof lantern details.

An example of ‘cool work’ materials would be thermically activated flat roof systems — such as those from the BMI Icopal TorchSafe range — which combine the use of thermically activated products, hot air welding and specially formulated primers.

The development of such Safe2Torch compliant solutions, like thermically activated systems, reveal the importance of manufacturers in helping frame Safe2Torch. This involvement was imperative as, however laudable the scheme, it would be impossible to implement practically without contractors having access to materials and product ranges suitable to satisfy Safe2Torch specifications; or design and technical support services.

Membrane technology

The development of thermically activated bitumen has been a significant development in membrane technology, allowing combustible and sensitive substrates and details to be covered ‘cold’ and keeping all surfaces free from fire risk during application. These innovative membranes are manufactured from dual compounds of SBS-modified bitumen to the upper surface, combined with a high tack, low activation thermically activated compounds to the lower.

For the decks, high-performance specially-formulated primers improve the bond adhesion of thermically activated self-adhesive bituminous membranes. Primers are available in both brush and roller applied or spray applied variants to suit the installing contractor’s preference.

Outside exclusion zones, capsheets will still generally be torched. They are available in high fire-resistant formulations that provide a fire protection layer, shielding the roof from both spread of flame and fire penetration.

When designing flat roofing, observation of Safe2Torch requirements and utilisation of proprietary design and specification services — and systems such as BMI Icopal TorchSafe — will help meet the statutory responsibility to manage risks created through those designs under the CDM 2015; not to mention greatly reduce roof fires and the high costs — personal and financial — that can ensue.

Daniel Tucker is Systems Product Manager at BMI UK & Ireland