Roland Jackson, Commercial Director of roofing, waterproofing and insulation specialist at Soprema, discusses alternatives to copper and why local authority specifiers should consider them for new-build and refurbishment projects.

For every public sector construction, refurbishment or maintenance project, design ambition has to be balanced with the principles of best value. Local authorities are the guardians of landmark buildings, as well as the public purse, which not only means making specification choices that assess build costs against visual impact and architectural context, but also means considering the financial implications of those choices during the programme and throughout the service life of the property.

It’s the role of the construction supply chain to develop new products that fuel creativity, practicality and sustainability. By re-thinking traditional materials to pioneer practical alternatives with a comparable aesthetic, the supply chain can open up new specification options that make eye-catching features more viable against best value criteria. When it comes to copper it’s now possible to achieve the look with a more cost-effective and sustainable alternative.

Copper vs Synthetic

Copper vs Synthetic

Copper has been a versatile and prestigious building material for centuries. Eye-catching, hard-wearing and recyclable, it ticks lots of boxes for both aesthetics and practicality. However, when it comes to designing a roof, the pitfalls of specifying copper can sometimes outweigh the benefits and, for public sector assets where it’s necessary to refurbish existing copper features without altering the building’s appearance, this can be a difficult barrier to sympathetic specification.

The first — and often biggest — issue is cost. Copper is a material that will offer excellent longevity, but it can substantially increase the build costs of a project. Using a synthetic alternative costs 50-60% less per square metre.

The high monetary value of copper also creates risk following completion. Like lead, copper is often stripped from buildings to be re-sold. At Leigh Road Baptist Church in Leigh-on-Sea, thieves stole the copper used to refurbish the spire just before the scaffolding was removed. To protect the church from further incidents of theft, the spire and cupola were then refurbished using Soprema’s FLAGON Copper Art. The synthetic waterproofing membrane has provided high performance and the appearance of copper at a lower cost and risk. A synthetic membrane is more difficult to remove and, as it has no value as a scrap material, it is not attractive to thieves.

Buildability and design potential

While copper’s natural aging is part of its appeal for some, the patina that develops is not always considered a benefit. A synthetic membrane, impregnated with copper particles for a genuine appearance, provides a durable and high performance alternative that will retain its freshly-built aesthetic for decades.

A synthetic membrane is also more temperature-stable than traditional copper. The natural expansion and contraction of copper can result in distortion to the roof or copper feature. During the summer months, it’s natural property as a conductor can also increase the building’s solar gain, which may affect indoor temperatures and cooling load requirements, impacting on operational costs and comfort levels.

While copper is a soft and malleable metal, it cannot provide the flexibility of a synthetic roofing membrane, which will flex to any shape, including complex curves. The membrane can also be cut to accommodate the contours of any building design.

What this means for creating landmark public sector buildings is limitless design possibilities, using ‘copper’ as an exterior feature, while providing a high performance and durable waterproof surface with an extended service life.

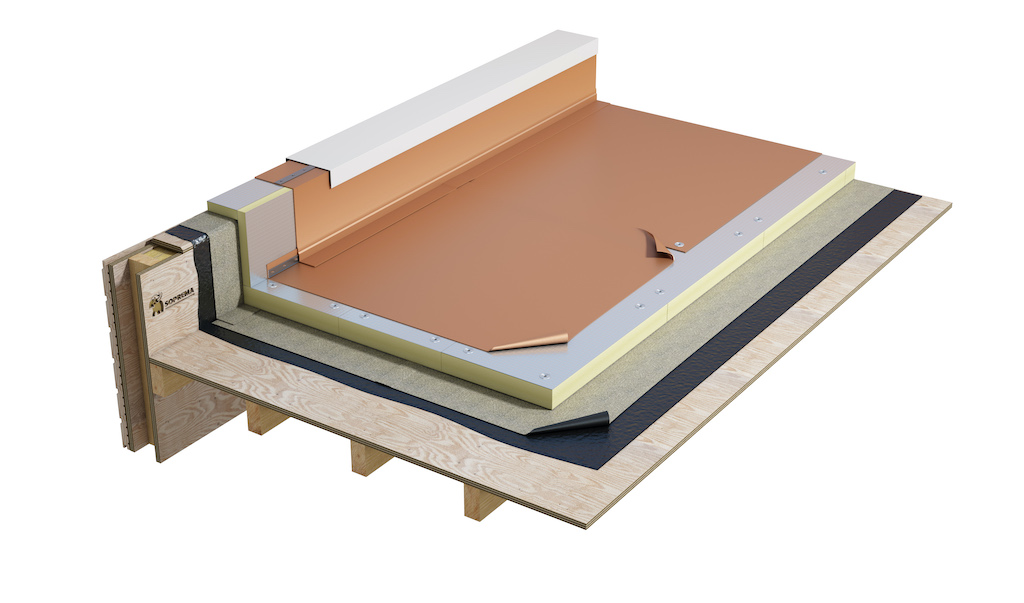

FLAGON Copper Art is suitable for either fully-adhered or mechanically-fixed installations, and can be installed as a standing seam roof with joints hot-air welded onto the membrane following installation. For example, the cupola at the Baptist Church in Leigh-on-Sea was installed as eight triangular pieces of membrane with standing seam joints installed to complete a perfectly symmetrical feature.

There will always be a place for traditional construction materials but, as the supply chain steps up to provide alternatives, there is an opportunity for public sector specifiers to achieve the wow factor they’re looking for at reduced cost, risk and maintenance.