Matthew Evans, Head of Technical GB at Kingspan Insulation UK, offers advice on delivering better value and performance in flat roofing.

Flat roofs are a common feature of many public buildings, including schools and hospitals. When designing these features, either for a new building or as a replacement for an existing roof, it is important to ensure the construction provides effective drainage and protection against heat loss. Tapered insulation systems can meet both of these requirements in a single, lightweight solution which, as new research has now shown, can be as much as 43% cheaper than alternative construction approaches.

Flat roof requirements

Despite their name, flat roofs are almost always laid with a slight surface decline (typically up to 10%). This decline (fall) is essential as it allows rain, sleet and snow to be channelled off the roof. Without this, water will pond on the surface providing a fertile area for mould growth. If this is not addressed, the weight of the water can also cause the surface to deflect, worsening the ponding and potentially requiring the entire roof deck to be replaced. To prevent these issues, the final structure should achieve a fall of at least 1:80.

In addition to drainage, roofs can also act as a key source of heat loss from a property, so it is essential to ensure they are well insulated. Grants are now being made available for energy efficiency improvements under the Public Sector Decarbonisation Scheme and improvements to the thermal performance of existing flat roofs may be a worthwhile investment — providing long-term energy savings and reductions in running costs.

The specific thermal performance requirements for the roof will depend on its location (and therefore which regional building regulations it falls under) and whether it is a new-build, refurbishment or extension. When selecting insulation materials, keep in mind that those with lower thermal conductivities are more effective at preventing heat loss. This often means a slimmer thickness of insulation can be used to achieve the desired U-value.

Fall options

Traditional methods used to create a fall include timber firrings (angled timber battens) beneath a plywood deck and laying screed to a fall on a concrete deck. However, as the thermal performance requirements for these elements have increased, many contractors have now switched to tapered insulation systems, which deliver both drainage and insulation.

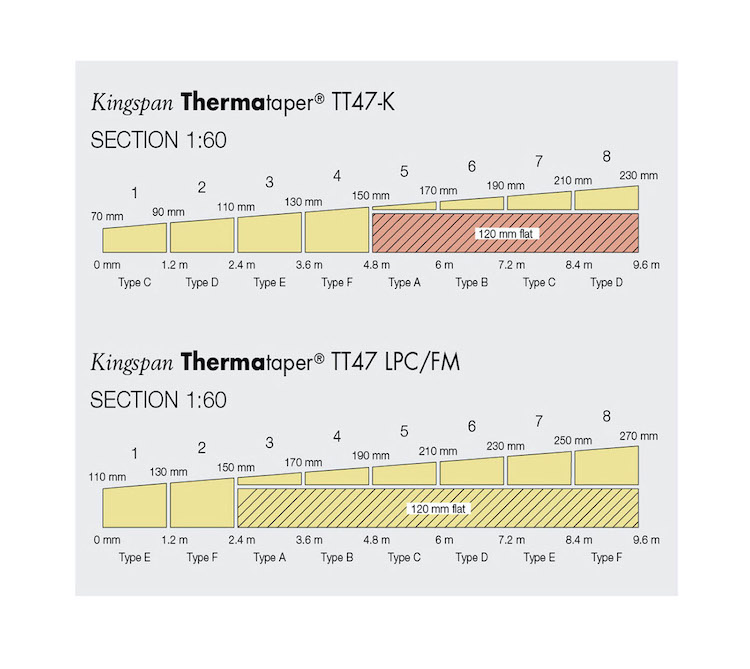

Tapered insulation systems typically include three types of rigid insulation boards: tapered, hip and valley and flat packer (which sit below the other types of board). Manufacturers will typically create a bespoke system layout, ensuring the roof drains effectively and reaches the U-value target with the slimmest possible build-up.

Cost analysis

Kingspan Insulation commissioned Currie & Brown to consider how these different approaches can impact project costs. The research considered four new-build case studies, including a hospital extension and office blocks, with concrete decks and roof areas of between 192 and 3,073m2. For each case study, they compared three warm roof constructions using cement/sand screed, timber firring and tapered insulation approaches. All of the constructions use polyisocyanurate (PIR) insulation and are designed to achieve identical U-values of 0.16 W/m2K.

In addition to the price of the materials, the Currie & Brown analysis also considered practical costs including labour in laying and waste disposal. The results are shown below:

|

Case Study |

Fall Method |

Above the Deck & Other Cost Impacts (£/m2) |

|

Hospital extension with roof area 192m2 |

Tapered insulation |

£140 |

|

Screed laid to falls |

£194 |

|

|

Timber firrings |

£172 |

|

|

Rebuilt office block with roof area 338m2 |

Tapered insulation |

£163 |

|

Screed laid to falls |

£206 |

|

|

Timber firrings |

£178 |

|

|

New build office block with roof area 3,073m2 |

Tapered insulation |

£136 |

|

Screed laid to falls |

£194 |

|

|

Timber firrings |

£162 |

|

|

New build office block with roof area 1,512m2 |

Tapered insulation |

£136 |

|

Screed laid to falls |

£182 |

|

|

Timber firrings |

£165 |

In each case, the tapered insulation system was shown to be the most cost-effective option, providing savings of as much as 43% compared with the screed system and £15-£32 per m2 (up to 23%), when compared with the timber firrings.

Additional benefits

The research also highlighted that the tapered insulation system could provide clear practical advantages over the cement/sand screed option. It is estimated that the screed method takes around one month to dry per 25mm thickness, leading to drying times of up to 195 days for the case study applications. Whilst a quick drying solution can help to reduce this time, it will also significantly raise costs. In contrast, the tapered insulation system is installed with a dry installation process, meaning no time is lost waiting for drying and installation is less likely to be impacted by adverse weather.

The tapered insulation system was also shown to weigh as little as around 3% that of the screed system. In the case study with a roof area of 3073m2, for example, the weight of the screed system was expected to be over 1,000,000kg compared with just 23,000kg for the tapered system. This will almost certainly have significant additional implications for the design and cost of the structural frame and foundations, which were not considered within the Currie & Brown analysis.

Top-down performance

With energy performance requirements set to significantly tighten for all buildings over the next decade, it is important to consider what steps can be taken now to future-proof new buildings. This includes taking advantage of funding opportunities such as the Public Sector Decarbonisation Scheme to raise the performance of existing buildings. Improvements to the building fabric should be carefully considered as part of this and, as the Currie & Brown research shows, tapered insulation systems can provide a simple and cost effective solution to addressing both drainage and heat loss from flat roofs.