With assistance from the Welsh Government’s Inward Investment team, Bridgend has been chosen as the location for Thermify Cloud’s first heating system production assembly plant.

Thermify Cloud, led by Travis Theune, a Silicon Valley entrepreneur, has designed a revolutionary low-carbon heating system that will provide households with affordable heating and hot water by using the waste heat from a bank of computers that are incorporated into the heating system.

Thermify Cloud is setting up its first production assembly plant at the Sony UK Technology Centre at Pencoed, near Bridgend. The company plans to employ up to 30 people and produce 1,000 Thermify HeatHub units in its first year.

The world-famous Raspberry Pi computer, manufactured at the Sony plant, will be used in the Thermify heating system, and Sony will also manufacture the electronic circuit boards for the system. In addition, the SPECIFIC Innovation and Knowledge Centre at Swansea University will support Thermify’s research work and test programmes.

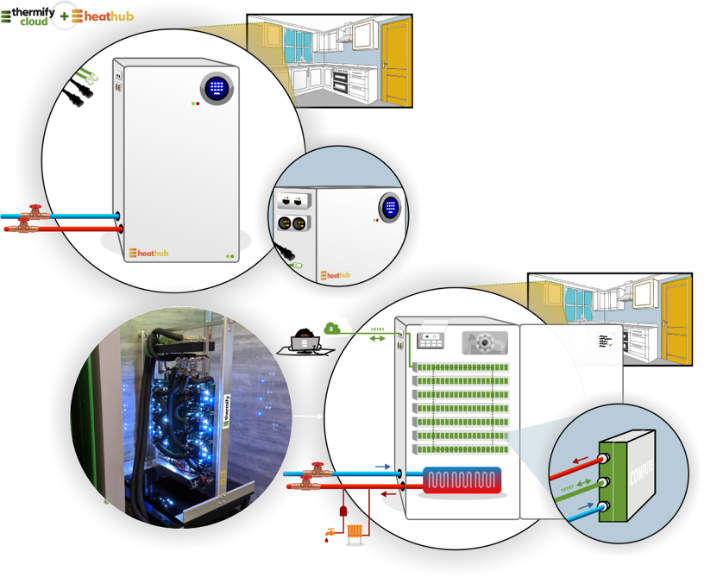

Thermify’s HeatHub system is a radical new solution to replace gas boilers; it is a “distributed data centre” and a heating system in a single unit, installed in a householder’s home. It uses the wasted heat from the bank of computers in the HeatHub, that is deployed in the householder’s home, to provide hot water and heat for the very same home. The electricity that is used to power the computers is used twice and is paid for by Thermify. At the same time, it will generate new revenue from cloud computing.

By using energy twice, HeatHub offers customers an affordable heating system and, if deployed widely, will help reduce the levels of fuel poverty that exist in Wales and the rest of the UK.

It’s been designed as a mass-market solution that will be a drop-in replacement for a domestic gas boiler in energy efficient homes, and at the same time carry out IT/computing tasks for all types of users – for example financial service companies, retailers and media companies. Thermify is aiming to produce 40,000 HeatHub units per annum within the next 3-5 years.

Travis Theune, CEO of Thermify Cloud said: “With the UK needing to move away from gas heating to reach Net Zero and switch to low-carbon heating, Thermify has a great solution to offer the market Importantly, it gives customers an affordable heating system. It will give households monthly savings on their energy bills, reduce their carbon footprint and support a cleaner environment.”

“The combination of low carbon, affordability and technology means that we have a fantastic opportunity to build a strong and long-term business in South Wales.”

“The support and encouragement of the Welsh Government has been immense, as were the responses from Sony, Raspberry Pi and Swansea University. They immediately saw the potential of our HeatHub system, not only in the UK but in overseas markets too, and they all wanted our HeatHub to be stamped Made in Wales. Our technology can play its part in the UK’s efforts to decarbonise heat, as set out in the Government Heat & Buildings Strategy.”

Welcoming Thermify to Wales, Economy Minister, Vaughan Gething said: “The Welsh Government has been working with the company for some time to secure their move to Wales. This is yet another example that Wales is firmly open for business and we will remain open and competitive for inward investors from around the world. We’re determined to help create new green jobs in the industries of the future. We are really excited by emerging smart energy systems and how they are integrating and interlinking with transport and heat systems. Smart technology allows homes and businesses to generate, store and use energy in ways not previously available – a win for businesses, consumers and crucially the environment.

“We recognise the international role played by our universities and the economic importance of the beneficial links they provide to the wider world through students, research and business relationships. Thermify will be able to benefit from Swansea University’s industry-leading SPECIFIC energy technology research and full-scale demonstration capabilities.”