The pre-blended one-coat render system from Saint-Gobain Weber was used in the construction of a £12.5m new leisure, sports and swimming pool complex recently opened in Flitwick, Bedfordshire by Central Bedfordshire Council.

Saint-Gobain Weber say the project benefited from significant savings in time and money from using the weber.rend OCR system as background render for substantial sections of tiling in the pool areas, as well as the preparation of larger areas of render prior to the application of painted finishes. The pump applied system has been developed to achieve faster application times, thus helping to save on labour costs and speed up the construction programme.

The render is designed as a technical basecoat render for a wide variety of stable substrates including brickwork, blockwork and concrete, and provides an ideal background for all the company’s finishes, masonry paints and other surface coatings. The render is based on Portland cement, lime and sand which is factory blended to ensure consistency and conforms to British Standard mix formulas BS5262 and BS5492. It is available in two grades suitable for external rendering or as a tile backing render. The weber.rend OCRT, a lime-free version for tiling background that conforms to BS5385, was also used on the project.

With the addition of clean water on site, these bagged products require one coat to deliver render thicknesses of between 8 and 20mm with a two to three day curing time.

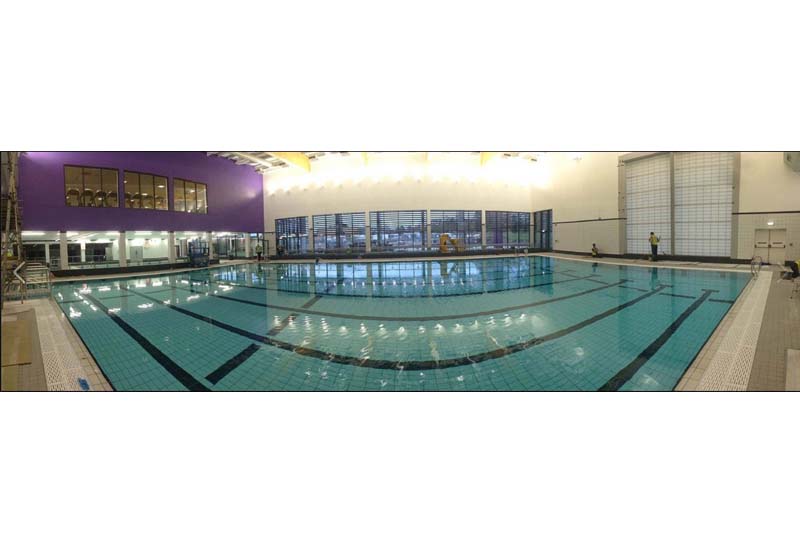

The new leisure centre opened earlier this year and includes an eight lane, 25 metre swimming pool; separate learner pool zone; sports hall; fitness suite with 120 cardio machines; three dance and exercise studios; two squash courts; a 10 metre high indoor climbing wall, crèche and cafe area.

The main contractor on the project was SDC Builders, based in Bedford. Project manager Paddy Leslie credits the product as well as the skills and experience of the specialist applicator Jordaya Contracting: “Pool halls are a difficult build project in terms of both design and access, and also in terms of scheduling the various trades, but the weber.rend OCR and Jordaya got the job done for us. The pumped system has benefits in that there is more controlled mixing and application with less waste.”

Sean Denton of Jordaya Contracting, who is regularly involved with major civic build projects such as the Flitwick Leisure Centre, added: “These are big builds that need to be delivered quickly after long periods of planning and consultation. We proposed and used Weber products at Flitwick Leisure Centre as we have used these products many times and know we will achieve the consistency and ease of material handling along with the factory formulated back-up that we could not get with site mixed products.

“We applied weber.rend OCRT on 2,000m² for tiling background; weber.rend OCR on 500m² for painted walls and brought in weber.rend LAC render mortar for 200m² of low level concrete walls which we treated first with weber.rend aid to ensure a strong bond.