Elta Fans is pioneering the industry toward Net Zero as it becomes one of the first to offer TM65 Embodied Carbon reports for its building services products.

Created by CIBSE in 2021 (the Chartered Institute of Building Services Engineers), TM65 Embodied Carbon is a calculation methodology that helps assess how much embodied carbon is associated with products.

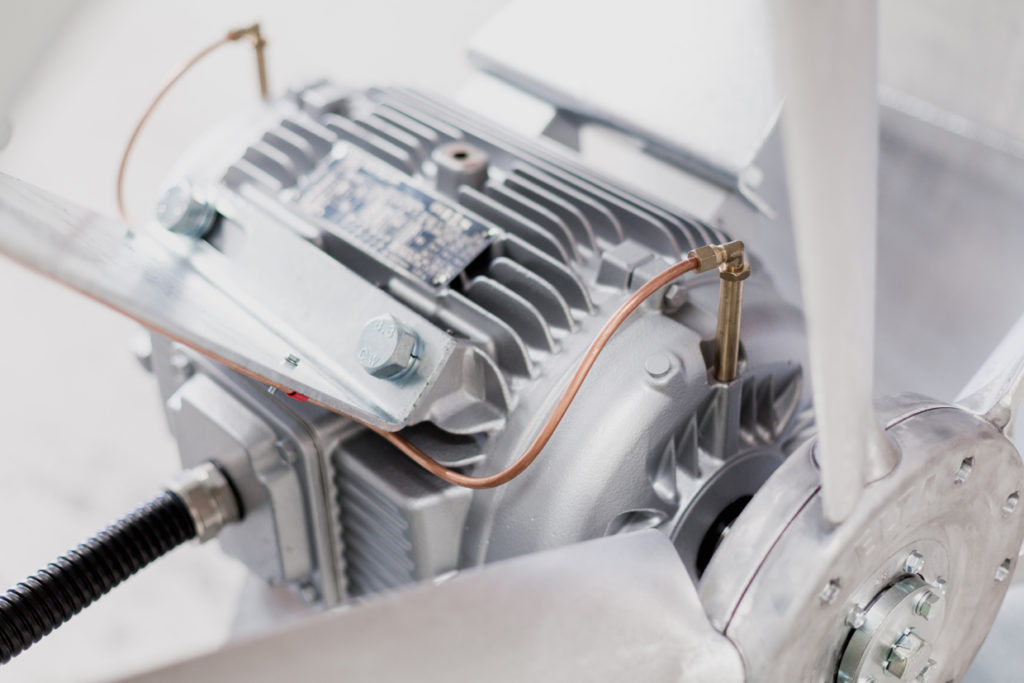

Following extensive development, Elta Fans, the leading air movement and ventilation solutions manufacturer, can generate TM65 Embodied Carbon reports for its air handling units (AHU) and fan ranges. The reports will help consultants, architects and specifiers to get a fuller picture of how much carbon is being generated on new construction projects.

The project is being spearheaded by Luke Temple, Project Engineer at Elta Fans, and David Millward, Group Product Manager at Elta Group. On the development and why they embarked on the project, Luke said: “As one of UK’s biggest manufacturers of ventilation equipment, we know we have a crucial part to play in protecting our planet. While embodied carbon is not new, up until very recently, there hasn’t been a standardised or accurate way of being able to show how much embodied carbon building services solutions generate over their lifetime.

The project is being spearheaded by Luke Temple, Project Engineer at Elta Fans, and David Millward, Group Product Manager at Elta Group. On the development and why they embarked on the project, Luke said: “As one of UK’s biggest manufacturers of ventilation equipment, we know we have a crucial part to play in protecting our planet. While embodied carbon is not new, up until very recently, there hasn’t been a standardised or accurate way of being able to show how much embodied carbon building services solutions generate over their lifetime.

“Since the announcement of CIBSE’s TM65 methodology, we have worked tirelessly to take the assessment criteria and set up our own calculator. Consultants can now come to us for embodied carbon reports when they need to demonstrate these figures in plans. A key benefit is it helps make it easier to compare products against each other based on how much carbon they release in their production through to end-of-life. Ultimately, the reports will get projects from design and specification stages through to building much easier, and is another stepping stone towards Net Zero.”

Available as PDF datasheets, Elta Fans’ reports are calculated through a number of variables such as material weight and assesses the embodied carbon generated at each stage of a products’ lifecycle. This includes going from production to manufacturing, through to transportation, maintenance while in-use, and end-of-life recyclability potential.

“While stating how much embodied carbon is contained in our products is not currently a mandatory regulation, we see greater awareness amongst some of our customers and we anticipate that it will form part of future sustainability and efficiency targets,” said David. “With a wealth of data, not only are we able to assist consultants on their projects, but it also means we can build on our own manufacturing processes, helping us to design more eco-efficient solutions.”