Previewing presentations from a forthcoming seminar series, Niall Crosson, Group Technical Manager at Ecological Building Systems and Michael Foerster, Engineer Head of Applications Technology at pro clima, discuss the need to ensure unforeseen moisture trapped during the build phase can be released from the building envelope to avoid structural damage over time.

The summer heatwave not only resulted in some prominent tan lines for those working on public sector construction sites; but it also reduced the risk of moisture becoming trapped within the structure during build programmes currently on site.

In the typical UK climate, however, such an opportunity to build during prolonged periods of dry weather is rare. Usually, rain, atmospheric moisture and high humidity are inevitable during any construction project and this can often lead to moisture becoming trapped within the structure where, over time, it can cause issues with damp, mould and the formation of spores that will lead to rot over time.

Moreover, while the UK’s wet climate is the main cause of moisture penetrating the structure during the build phase, it is not the only culprit. Moisture from plaster and screeds can also lead to high humidity during construction, contributing to moisture-related structural damage and reduced service life of the property, unless specification of the building fabric and higher levels of quality control on site enables the gradual release of moisture to the outside.

Trapped moisture issues

In all construction projects, getting the building watertight is a high priority but, in the wet and windy climate typical of so much of the UK, moisture may have already penetrated structural elements such as timbers and insulation. Indeed, around 90% of building failures are due to issues caused by trapped moisture.

Often the vapour control layer (VCL) is seen as the catch-all remedy for managing moisture issues within a property but if moisture has penetrated the structure during the construction phase, this can actually trap the moisture within the wall or roof build up.

This is because all vapour check membranes may allow some moisture into the structure due to air leakage, during construction, with the combination of high humidity, drying screeds and plasters and cold temperatures creating moist conditions on site, especially if some or all of the build phase takes place over the winter months. If the vapour control membrane specified does not allow the moisture that has penetrated the structure during construction to ‘back dry’ to the interior when conditions allow during the warmer summer months, the moisture within the structure can become permanently trapped in the building envelope.

While the vapour trapped may only represent relatively small amounts of moisture, its impact can be significant over a longer period o time. For example, trapped moisture can lead to issues with damp insulation, affecting the building’s energy efficiency because the insulation does not perform to its designed capability. It could also lead to permanent mould and decay, resulting in reduced air quality within the finished building, creating a breeding ground for fungal or bacterial spores and potentially reducing the structure’s service life.

Hydrosafe solutions

To address the issues that can result from moisture penetration to the building structure during the build phase, the most effective specification methodology is to select a membrane that hinders the transfer of moisture into the building fabric during periods of high relative humidity, thereby limiting the root cause of the problems. It’s also essential that the chosen membrane enables back diffusion of any moisture that does enter the structure through unavoidable leakages, moist building materials and flank diffusion effects, enabling it to escape to the inside of the building following completion of the build phase, before it can cause structural damage or create the dank conditions that support spore growth. This is especially critical in scenarios where the construction has limited drying capacity to the exterior (e.g where impervious layers are used outside such as OSB or plywood).

At pro clima, we have created a term for this technology — ‘hydrosafe’ — and used this as a key element of the development of our airtightness membranes, including pro clima Intello Plus, which has recently achieved the renowned Passivhaus Institutes highest ever rating for airtightness during tests for Passivhaus approval.

Hydrosafe technology ensures that the building envelope is much more forgiving than specifications that include a standard vapour control layer or vapour barrier, because it provides humidity variable moisture protection, in particular at the building phase where humidity levels with buildings will be at their highest due to poured screeds and plastering.

During periods of high relative humidity in the winter, when it is wet and cold outside and warmer and drier inside, the hydrosafe vapour check also provides excellent protection against condensation. Then, during the warmer, summer months, when the relative humidity is lower, hydrosafe technology provides enhanced back diffusion capacity, enabling any moisture in the structure to dry out to the interior rather than remaining trapped.

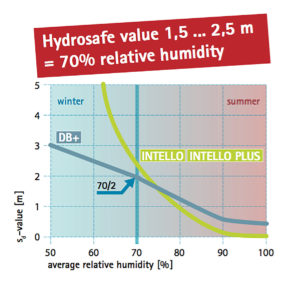

The technology is based on tangible building physics data, which has been used to measure ‘hydrosafe values’; a calculation to assess the vapour resistance of a humidity-variable vapour check at an average humidity of 70%. For example, an average humidity of 70% will be present if there is a humidity of 90% inside the building and 50% humidity on the opposing side of the vapour check adjacent to the insulation between the rafters. The German building code standard (DIN 68800-2) requires that a humidity variable membrane’s vapour resistance should be greater than 7.5MNs/g and less than 12.5MNs/g. This is the hydrosafe threshold and specifiers should ensure that humidity variable vapour checks, such as Intello Plus, performs within this range to deliver effective protection from moisture retention in the structure and all the associated problems it can cause, especially at the building phase.

Best practice

If you are unsure of how to specify a building envelope that delivers the benefits of airtightness without the risks of trapped moisture, you’re not alone; that’s why Ecological Building Systems and pro clima have teamed up with the BBA to host a series of CPD seminars. As the public sector continues to address the challenges of reducing maintenance, improving service life and enhancing building comfort in its property assets, a hydrosafe approach to vapour check specification is an essential element in designing robust, energy-efficient and mould free buildings.

For more information on the seminar events visit: www.intellosealofapproval.com