David Meacock, Technical Director at Cistermiser and Keraflo, outlines how the latest water management solutions are playing a key role when re-commissioning buildings that have been temporarily mothballed or repurposed to meet flexing occupancy levels.

While staff may be returning to UK workplaces in the highest numbers since the start of the Covid-19 crisis, levels remain far below pre-pandemic levels at just 23.3%. It’s abundantly clear that planning to return to something approaching ‘business as usual’ is presenting innumerable challenges for everyone involved in looking after buildings. As restrictions disappear it’s critical to ensure that public health continues to be protected, especially when it comes to the provision of safe water.

One potential health risk relates to Legionella in water systems that were been used during lockdowns, or that have been underutilised due to lower and flexing building demand. Buildings should have in place a risk assessment and a Water Safety Plan, but dormant water systems will result in bacterial growth, especially as we move towards warmer weather.

All aspects of a buildings’ water systems need to be reviewed before re-opening fully or in part. In some cases, these reviews will be carried out by teams of people on the ground. But for some more forward-thinking organisations, this critical work is being carried out by state-of-the-art cloud driven solutions, like LinkThru TMU from Cistermiser, which is being deployed in numerous educational, healthcare and public sector facilities across the UK.

What is TMU water monitoring?

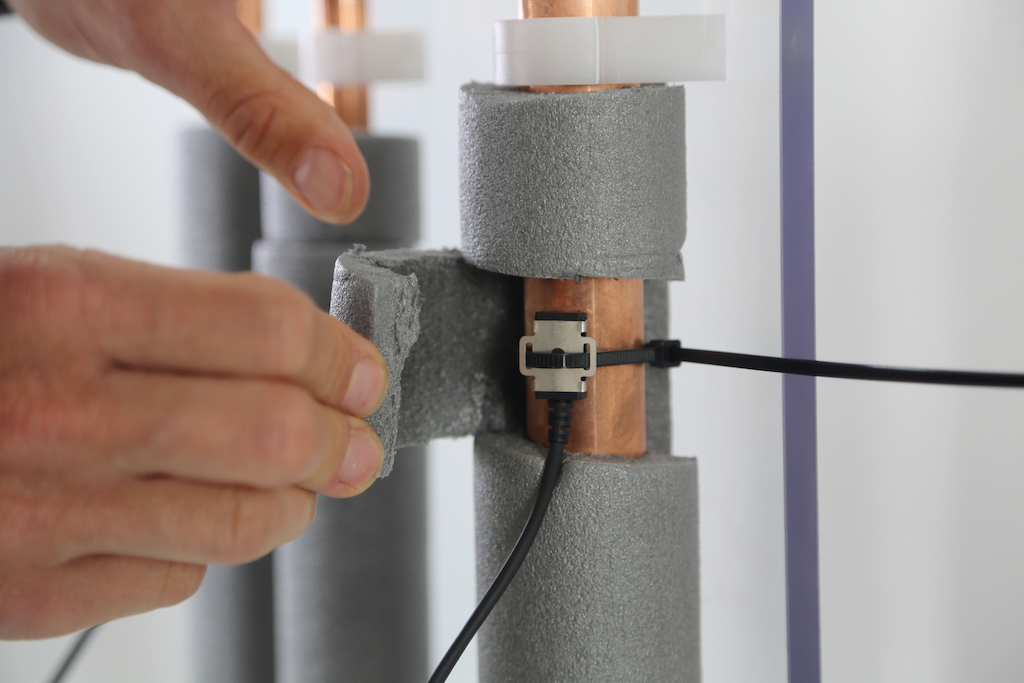

In short, Intelligent Temperature Monitoring Units (TMUs) deliver automatic wireless monitoring, providing real-time temperature readings on a computer screen, in order to track and monitor hot and cold water temperatures in pipework systems which are critical to risk assessments. A connected TMU can be retrofittable and is typically fitted onto water outlet pipework, distribution pipework including risers, calorifiers, cold water storage tanks and many other sentinel points across a building’s water system.

Each TMU takes a water temperature reading every 10 seconds and then sends temperature and flow event data to a cloud-based portal on an hourly basis.

Recorded data includes maximum, minimum and average temperatures. The sensor also records any flow events, such as outlets being utilised. The data readings are analysed by the device’s inbuilt software, batched and sent up back to the cloud, and then on to the user’s preferred interface, which might be a phone, tablet or PC. The powerful data delivered by installed TMUs can help to show where sections of a building’s water system have remained safe and are operating to specified parameters (and therefore do not need excessive flushing) and flag areas that may require specific attention.

Legislative requirements are of course also a primary concern — in developing the system we continually referred to HTM guidelines, for instance, in setting the software’s recommended default temperature ranges for outlet types. HTM and HSE L8 ACoP guidance also emphasises the need to ensure water doesn’t stagnate, and of accurate record-keeping. This means LinkThru users have peace of mind that they’re monitoring and recording what they need to in order to best protect against the threat of Legionella.

A sitting duck?

The other area of concern for public building owners and managers are water tanks. Where water is drawn directly from the mains supply it’s not so much of a challenge. But in larger facilities, we can often see up 20,000 litres of cold water stored in tanks on site. Pre-COVID, when buildings were at capacity, use of the water would have matched the tank size and performance ensuring optimised and safe flow rates. But now there could be significant amounts of water simply sitting still and not being used, which increases the risk of stagnation in the storage tanks. If these levels aren’t being monitored or controlled in any way, this creates a perfect environment in which bacteria thrive.

The single most important thing with a water storage tank is that the water should be turned over every 24 hours as a minimum.

Tank flex functionality

Delayed action float valves, like those from Keraflo, go a long way to helping with water turnover and lowering the water level in tanks if required, but to take tanks to the next level of safety you need to monitor what is happening in the tank and act accordingly. This is where the WRAS approved Tanktronic from Keraflo comes into it own. This is a device designed to work in harmony with the Keraflo Valves as a tank monitoring system or with the Electro-Mechanical Filling Valve for monitoring and filling.

The Tanktronic is a modular electronic tank management system, which provides a simple solution to monitoring water levels, volume and temperature through one connection. It can also manage and control tank filling and feed all this information back to your Building Management System or other third-party devices. The system also provides proactive alarms for high and low water levels and water temperature alerts.

It’s innovative ‘flex functions’ (aka holiday functions) means you can have different water levels for different times of the year, weekends, and even different days of the week. So if you know building footfall will be higher on say the first and last day of every week, you can set it to automatically manage this.

Despite its critical function, water management has traditionally been perceived as a problem-child, approached in a fragmented and sometimes inconsistent way across the sector. Now with the additional challenges discussed above, we aim to change this for good.