Sindar Singh, Product Line Director for Valve Technology for Doncaster-based Aalberts Integrated Piping Systems, discusses the importance of Dynamic Balancing Valves in HVAC systems and the latest solutions available to tackle the challenges facing HVAC professionals and local authorities.

Valve technologies continue to evolve and bring benefits for contractors and building users making entire systems more sophisticated and more efficient. Valves, in all their types, have been integral to heating and plumbing systems for centuries. The first valves were used in Roman times to help with the flow and control of water across their cities; it’s fair to say things have evolved somewhat since then.

What is a Dynamic Balancing Valve?

Now Dynamic Balancing Valves are bringing the latest upgrades to plumbing and heating systems. Defined as ‘a flow limiter that prevents overflow in the part of the system controlled by the valve’ it gives greater control and efficiencies in whatever system they are used.

It is different to a static balancing valve in that traditional valves are a permanent resistance within the system. Each valve must be calibrated individually and amending just one of them could change the flow through all the other valves potentially comprising the performance of the system.

Addressing the challenges

Addressing the challenges

The most sophisticated Dynamic Balancing Valves now support, and more often than not, address many challenges found by HVAC professionals and local authorities, such as problems encountered during installation, flushing and commissioning issues. Recognising that these can be prohibitive to successful system installation and maintenance, manufacturers are developing products that are tailored to the differing challenges and environmental pressures experienced within the industry.

These latest products ensure there is a constant flow rate for precise temperature control, optimise flow rates and reduce pump speeds to make them more energy-efficient and their simplified design and installation reduces costs and removes the need for commissioning valves. Combined these valves ensure environmental efficiencies are maximised and system failures all but eradicated.

Why they are important

The latest valve technologies not only drive system efficiencies but also bring added levels of capabilities when securing new contracts. By scoping the most sophisticated systems using the latest products on the market, the needs of contractors are also met allowing upfront installation costs to be delivered as part of the tendering process.

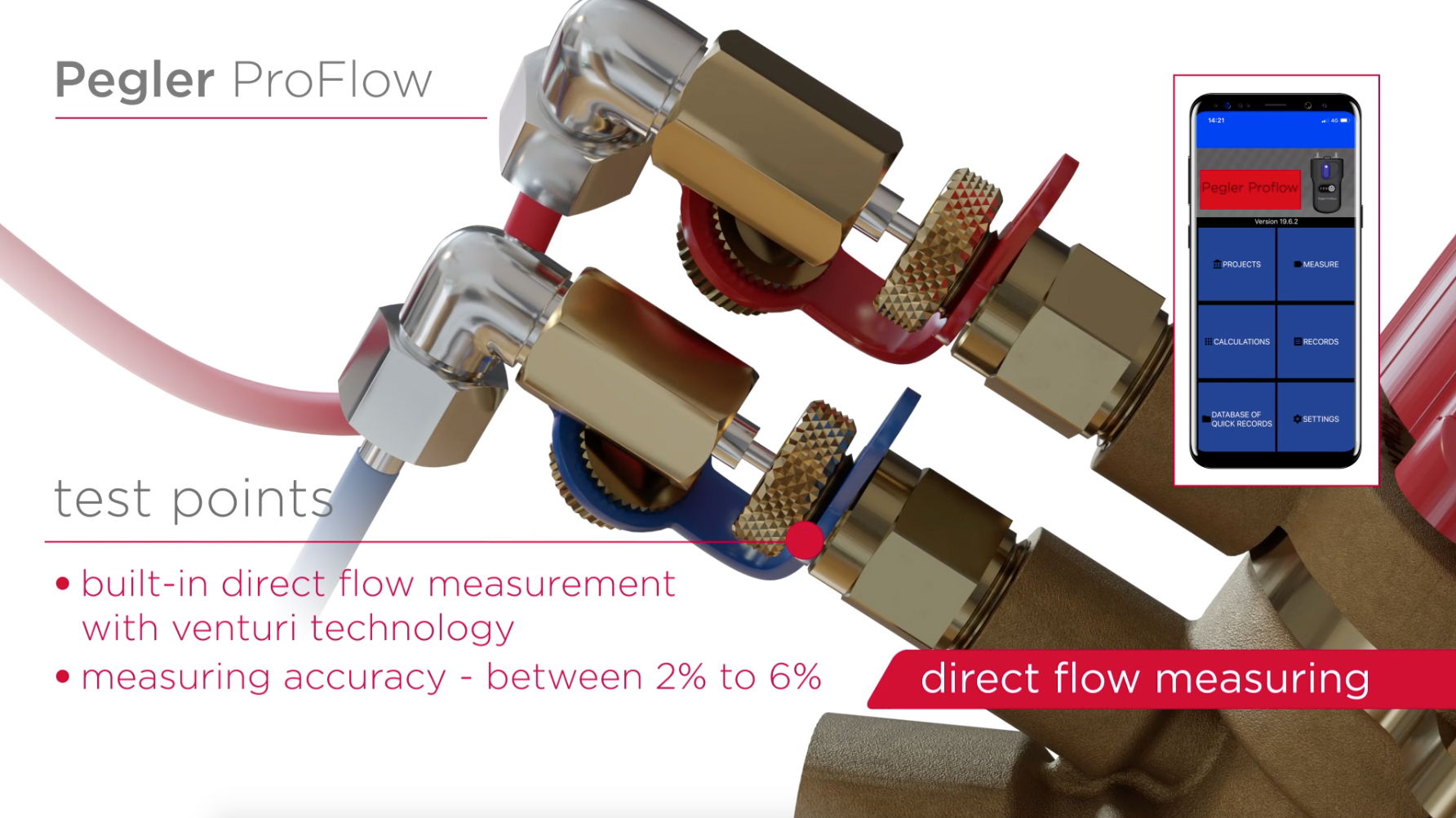

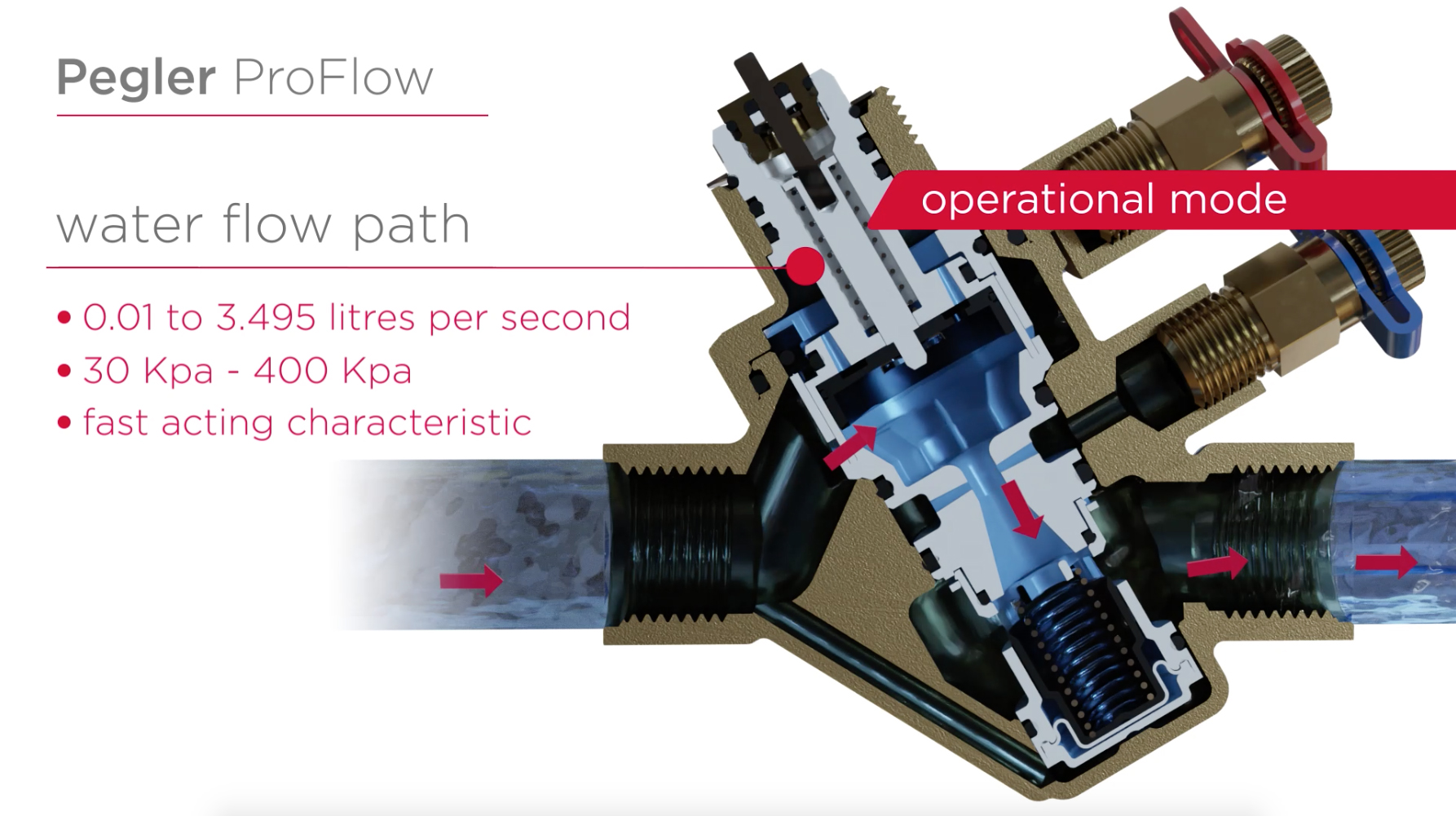

In addition to supporting business processes, the latest values give a combined pressure independent control valve with direct flow measuring in one body. Typically, they operate independently of changes in system pressure and feature an integrated in-line fixed orifice. This allows direct verification of presetting and actual flow operation, taking the guesswork out of measuring the flow further downstream to verify or adjust settings. Some also feature a fast flush cap to allow valve and cartridge access so that they can be removed prior to flushing.

The latest technologies

The latest technologies

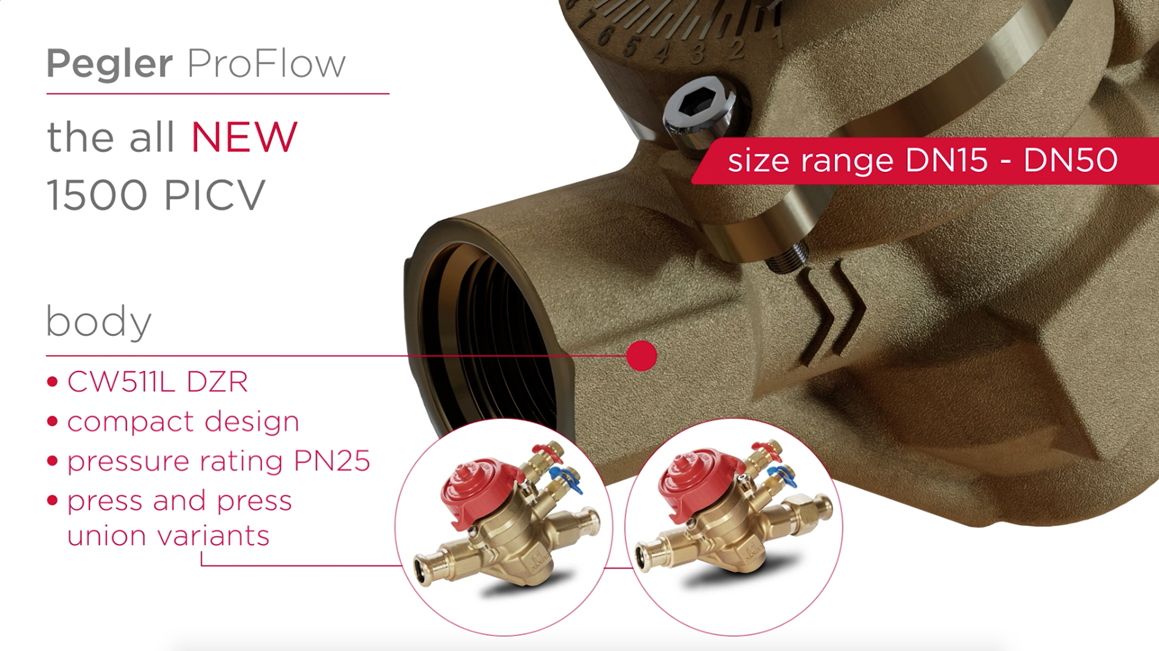

Valve technologies are now incredibly sophisticated with settings and monitoring often controlled through computer programmes and the best of which are manufactured in the UK, and more specifically in Doncaster. Hot on the heels of the Pegler ProFlow PICV 1600, Aalberts Integrated Piping Systems has launched its Pegler ProFlow PICV 1500, which benefits from the trusted Pegler technology but also provides an equal or approved solution to demanding project costs.

The Pegler ProFlow 1600 Valve range utilises innovative technology to address whole project costs from specifying, installing, balancing and maintaining a HVAC system. The new Pegler ProFlow 1500 has a range flexibility of DN15 to DN50 and offers a PN25 pressure rating. Its location of test points also allows direct flow measuring utilising the built-in Venturi technology. Both direct flow rates and differential pressure loss can be verified using the Pegler ProFlow BC3 balancing computer.

The new product is available with a full range of connections utilising VSH Xpress, providing flexible installations in any desired position and due to its design, the valve can be installed directly onto bends, reducers, and flexible hoses.

Pegler, a renowned heritage brand, has been a pioneering force in the industry, delivering reliable, innovative solutions, and has been manufacturing in the UK for over 120 years.