Richard Crosby, Director of construction consultants blacc, looks at how a pioneering consortium could transform the way schools are designed, procured and built offsite.

The innovations developed by the Seismic Consortium have been unveiled and have been hailed as a trailblazer for transforming construction. Seismic was established to carry out research and development into the increased use of standardisation to help reduce costs and lead times, and radically improve productivity in the delivery of outstanding schools.

An innovative open source app has now been launched for the design of primary schools, and a universal connection solution and standardised structural frame for schools built offsite.

Project partners

The project was funded by UKRI through the Industrial Strategy Challenge Fund and Innovate UK. The partners involved in the Seismic initiative recognised its potential and invested significant resources into the initiative.

• The original concept was developed by blacc who then provided project leadership.

• Leading offsite specialists The McAvoy Group and Elliott collaborated to standardise the structural components for schools built offsite, with a view to expanding the market and de-risking offsite for clients. In an unprecedented move, these partners successfully combined their offsite manufacturing expertise for the success of the project.

• The Manufacturing Technology Centre (MTC) co-ordinated the bid submission and was a catalyst to create the consortium. The MTC gave the partners the opportunity to think beyond how schools have been delivered previously and apply more manufacturing principles to the construction of new schools, helping to develop more efficient processes.

• Bryden Wood provided digital expertise and led the development of the technology for the configurator.

Standardising offsite construction for schools

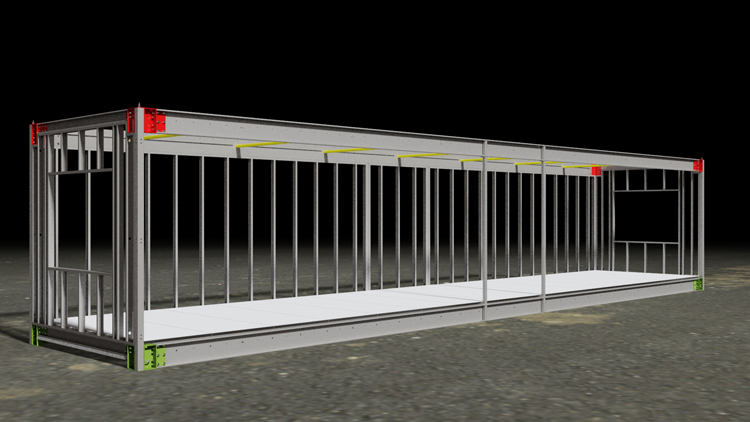

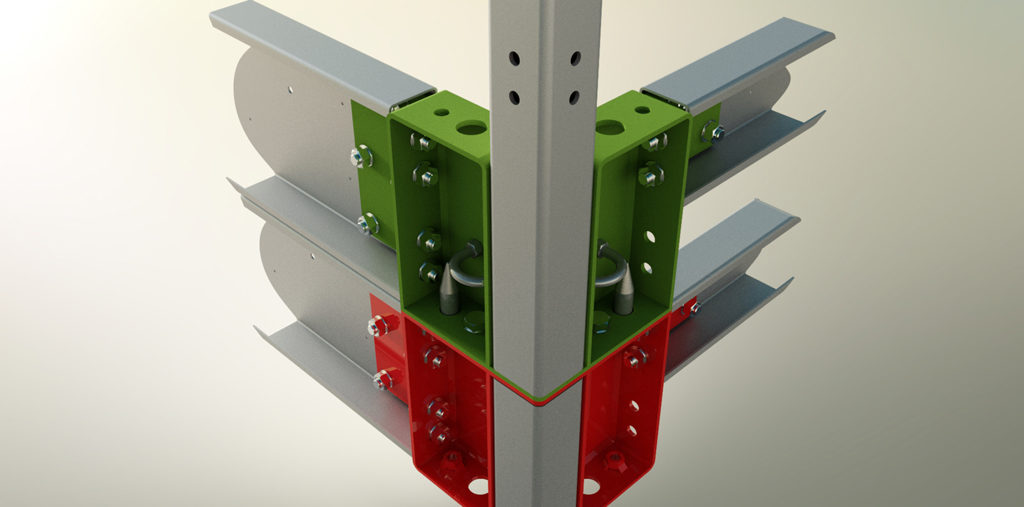

The starting point with the framing solution was to engineer a single, standardised way for McAvoy and Elliott to interconnect their respective modular building systems. An engineered solution was developed to connect each of the steel frames that make up a module — and to interconnect each module vertically and horizontally. The result is fewer welded joints and connections — which means less steel, less weight, faster assembly and therefore reduced cost.

The framing solution has been standardised around building clusters developed by the Department for Education (DfE). It has a single width and height, and three length options to suit schools — using the same connection solution.

The principle of standardised, manufactured components is that greater volumes will drive down costs and simplify procurement. For example, the DfE can pre-order a series of modules from a number of manufacturers that will be available ‘off the shelf’ for faster building assembly when a site receives planning.

Productivity, cost and environmental benefits

By rationalising the design of the steel frame, the number of components have been reduced. This means faster assembly in the factory — increasing productivity by up to 50%. Work on site to interconnect modules is also more efficient.

Research has shown that this approach significantly reduces the number of frame components and will therefore use 25% less steel. The reductions in steel components and assembly time generate a cost saving for these elements of up to 25%.

With fewer components, the weight of the modules will reduce by 25% with no compromise on structural rigidity — resulting in 25% lower carbon emissions for the offsite construction of an average 40-module school. This is equivalent to 155,000 miles of car driving or 17 flights from London to Sydney.

The Seismic School Configurator

An innovative open source app has been developed which enables the full spectrum of community to get involved in the design of primary schools. The Seismic School app is a user-friendly, free web-based tool developed to accelerate the initial design and feasibility stages. It will enable anyone from architects, planners, manufacturers to teaching professionals, parents and pupils to configure a primary school building that will precisely meet their user needs on a specific site in compliance with DfE and regulatory requirements.

The tool reduces the time and cost of the initial design phases from weeks to minutes and democratises the input of stakeholders by including them in the process.

Inspiring future innovation

Sam Stacey, Challenge Director – Transforming Construction at UKRI, said: “Seismic is a powerful example that the targets set out in the Construction 2025 Strategy are achievable. It is one of the first Innovate UK projects under Transforming Construction to be completed and demonstrates that this level of collaboration is the future of construction.

“The initiative has been a tremendous success and has hit all of the targets for Transforming Construction. The partners have demonstrated an unprecedented level of collaboration which we hope will inspire other forward-thinking projects to help innovate in construction and produce more efficient, sustainable and affordable buildings.”

“These innovations have the potential to change the way education projects are designed, procured and constructed, helping to meet the rising demand for school places and increase capacity in the construction industry.”

“The commitment, investment and R&D capabilities of each of the partners has been very impressive. Seismic has shown how by working together as an industry, even greater progress and innovation can be accomplished.”

Next steps

The benefits are already being realised in new DfE procurement frameworks. The team is in the process of completing testing of the framing solution. The next stage is collaboration with steel fabricators to develop the standardised components and establish a supply chain to make these available to the offsite market in the coming months. This approach will aggregate demand to reduce cost.

The longer-term aim is to develop a ‘product family’ for different types of buildings, such as residential. The team also has aspirations to ‘componentise’ other parts of a school building to offer a whole school solution, including walls and roofs.