Wall breather membranes are an important part of the design of building facades. Not only do they provide a temporary line of protection to the whole of the external wall to prevent water penetrating and damaging the exterior of the building during the construction process, but breather membranes can also significantly reduce the risk of interstitial condensation with the structure, allowing water vapour to escape into the vented cavity. Over the life of the building, breather membranes provide a second line of protection against rainwater penetration after the external facade is built.

There are many different types of breather membranes available, including reflective, insulating membranes that can help achieve low U-values to meet new stricter targets of Building Regulations Approved Document Part L for use with different building construction types such as timber frame, Structural Insulated Panels (SIPs), Cross Laminated Timber (CLT) panels and light gauge steel frame construction.

It’s also advisable to evaluate the products available in terms of their tensile strength, which illustrates how strong and flexible the membrane is, and their UV stability which relates to how long the product can be exposed during the construction process before being covered. The latter is a particularly important consideration for high-rise schemes where the facade materials may be exposed to the elements for longer as construction work progresses.

Hand in hand with these high-rise schemes or any development over 11m is the subsequent development of flame-retardant external wall breather membranes that offer fire-resistant solutions. These products provide additional peace of mind and more importantly for local authorities and specifiers working in the public sector, can help future-proof buildings in terms of both their safety and compliance with the evolving regulations.

Role of breather membranes in fire protection

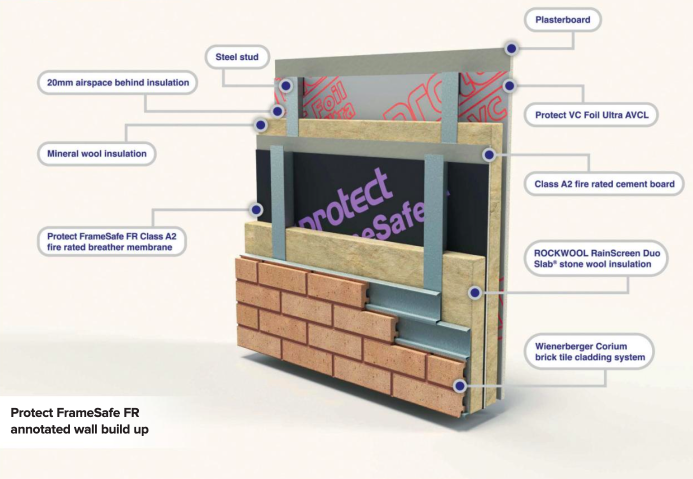

A breather membrane that offers not only waterproofing but additional fire-resistant properties can contribute positively to the overall fire safety performance of a build. Installed on the external side of the frame to integrate with the facade wall structures, they are particularly suited for use in higher risk buildings, such as high-rise residential accommodation. They are also an ideal solution for retrofit projects such as older social housing blocks which, as well as being more likely to suffer from damp condensation, could also have a fire risk.

The current Building Regulations Approved Document Part B for fire safety states that external wall membranes must achieve at least a Class B fire rating for structures over 11m. With an update to these regulations likely to ensure the continued future safety of constructed buildings, it is important to consider the long-term fire resistant performance or any specified systems, ensuring the products used are future-proofed against regulation change.

The increased availability of Class A fire-rated membranes such as Glidevale Protect’s new FrameSafe FR A2 product does make this process easier but as always, it’s more important to demand full transparency from manufacturers on how these products have been tested and their performance results. The devil is in the detail and full disclosure is essential.

Understanding fire testing

Trust is everything and any reputable manufacturer should be able to provide a full breakdown of how their products have been tested. This information should be presented in a clear and accessible way but if in doubt, there are key questions to ask. Has the product been independently fire tested in a laboratory by a third-party? Has the membrane been tested both free hanging and as a part of a system in an end-use application? Has it been assessed on different substrates? What about the fixings?

As specialist fire-rated tape is required to seal laps, it’s also important to be clear if these products have been independently fire tested as part of the overall system. Although fire testing of the tape itself is over and above the requirements of Building Regulations, Glidevale Protect has included the tape used with its FrameSafe FR membrane as part of its fire testing.

Understanding the reaction to fire classifications is also important and it should be made explicit if an FR membrane is rated as a Class A1,A2 or B product and what this result is both free hanging and as part of a system with the membrane fixed to a substrate. To illustrate, the Protect FrameSafe FR membrane achieves Class A2-s1, d0 both free hanging and when mechanically fixed to both A1&A2 substrates in an end use application, offering protection against the propagation of fire. Class A2 materials like this have very limited combustibility and contribution to fire and products achieving Class A ratings should have been subjected to the most stringent tests covered by BS EN 13501-1 Fire classification of construction products and building elements.

As specified in BS EN 13501-1, for a lightweight product like a membrane, two different fire test methods are required to achieve a Class A reaction to fire classification. These are tests to ISO 1716 which assesses the amount of energy released when a material is completely combusted during a bomb calorimeter test and BS EN 13823 which assesses smoke production, flame spread and energy release. The BS EN 13823 single burning item test method simulates a fire starting in the corner of a room with material under test exposed to the development stage of a fire.

Which types of project can benefit?

Fire-rated external wall breather membranes are an important consideration from all public use buildings but particularly those that have been defined as ‘higher risk’ in the 2022 Building Safety Act, such as high-rise housing, student accommodation schemes, schools, hospitals and care homes. They also provide a practical solution for use on schemes in London where for many developments there is a combustible material ban on external wall structures of buildings. For housing developments where the property has a minimum separation distance of 1m to the relevant boundary, this also necessitates the need for a fire rated external wall membrane to be specified.

A breathable solution for fire safety

With fire safety in the frame and a critical aspect during and after construction, flame retardant breather membranes can play an important role in supporting and protecting the integrity of the building facades and the safety of building users by reducing the risk of fire spread and smoke transfer.

A robust fire safety strategy should be integrated from the initial designs stages of a project and provide a ‘golden thread’ of information throughout the construction and post-occupancy stages. Partnering with a manufacturer that can provide full transparency of how the product has been developed and tested, and technical support throughout the installation process is an important step on the journey to designing, constructing and maintaining safer buildings for all.

For more information, visit www.glidevaleprotect.com/framesafe or contact technical@glidevaleprotect.com